Our vision

Our vision is to revitalize and revolutionize the U.S. industrial sector using clean electricity with cost-effective, high-impact solutions created by our public-private partnership of scientists, engineers and technology developers, community organizations and labor unions. Electric heating is economical and supports a more resilient, capable manufacturing industry everywhere for everyone.

Our process

EPIXC is a catalyst for overcoming key barriers to electric heating adoption in manufacturing processes by advancing electric heating technologies, at a systems level, by reducing the levelized cost of electric heat.

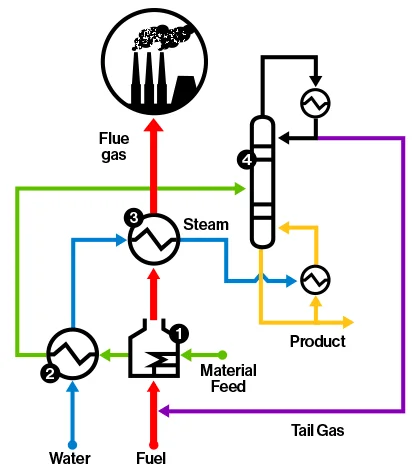

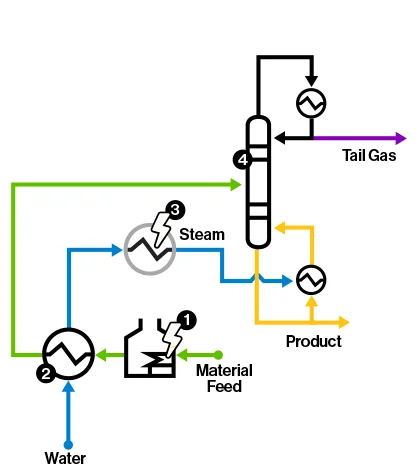

Transition from a conventional heating process to a electrified process can be more complicated than one-to-one replacement of the heater. There may be advantages/disadvantages with respect to raw materials flexibility or product quality, energy efficiency, number or needed parts, maintenance etc. The example below depicts a possible change when replacing a conventional boiler with an electric boiler.”

Traditional process

- Fired furnace reactor.

- Feed effluent heat exchanger.

- Heat recovery.

- Separator.

Electrified process

- Electrified reactor.

- Feed effluent heat exchanger.

- Electric boiler.

- Separator.

Meet the EPIXC team

Learn more about our executive leadership team and the exciting projects we’re working on together.