Targeted innovation and collaboration

The five largest energy-consuming industrial sectors in the U.S. are chemicals and petroleum refining, iron and steel, pulp and paper, cement and food and beverage. In the U.S. the energy consumed for process heating in these five sectors constitutes 95% of energy used for thermal processing in all industries. This concentration of energy use highlights the opportunity to make significant efficiency gains through targeted innovation and collaboration.

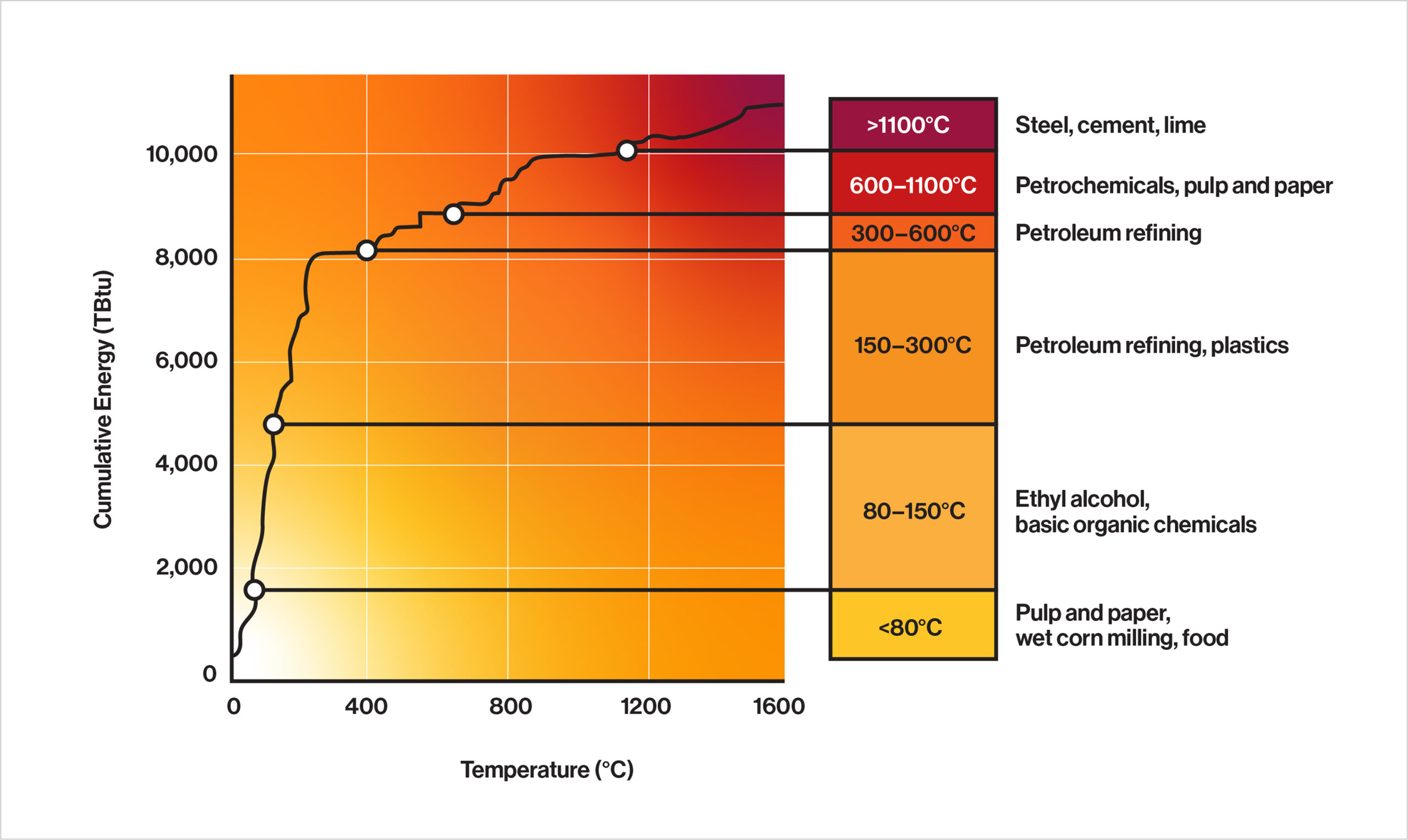

As shown in the figure below, the challenges and opportunities for electrified and hybrid process heating vary between sectors. For example, the energy demands of individual food and beverage production facilities are small compared to those in industries such as petrochemical, steel and cement. But the number of lower energy consumption sites far exceeds the number of heavy industry sites, and these sites are distributed more evenly across the nation. Due to this widespread distribution, according to a U.S. Department of Energy study, about 30% of cumulative process heating demand is for temperatures at or below 150°C — temperatures where heating is prime for electrification and hybrid heating using existing technologies that need to be integrated into processes and scaled.

Smelting, melting, calcining, hot rolling

Distillation, refining, cracking

Boiling, baking, frying pasteurizing, drying

Near-term and far-term impact

Through existing and emerging advanced electrified and hybrid process heating technologies, EPIXC is well positioned to advance the competitiveness of U.S. industries, reduce manufacturing costs, improve product quality, enable greater flexibility in heat process technology selection, and provide transparent impartial systems-level analysis to inform technology readiness and adoption decisions. EPIXC supports both near-term improvements and long-term advances of industrial thermal systems. EPIXC works with established manufacturers as well as electrification and hybrid technology developers and providers to drive energy efficiency and other benefits, such as increases in product quality and consistency, development of product offerings with unique and new properties, and simpler and more reliable heating equipment. These partnerships play a key role in accelerating the integration of high-impact technologies across a range of industrial applications.

References:

Akar, Sertaҫ, Parthiv Kurup, Matthew Boyd, Elizabeth Wachs and Colin McMillan. 2023. Renewable Thermal Energy Systems: Modeling Developments and Future Directions (Report 3). Golden, CO: National Renewable Energy Laboratory. NREL/TP-7A40-83021.

“DOE Industrial Decarbonization Roadmap,” U.S. Department of Energy, accessed March 15, 2024, https://www.energy.gov/industrial-technologies/doe-industrial-decarbonization-roadmap.

Join our mission

If you are interested in joining our mission, become a member today!