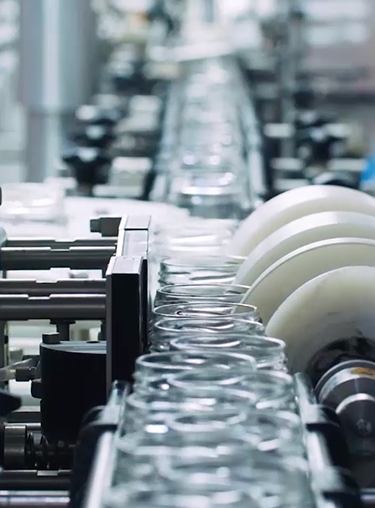

Food and beverage

Food and beverage energy demands

The food and beverage industry includes processing facilities such as bakeries, dairies, seafood, grain milling, fruit and vegetable preserving and more. Thermal processing using hot water and steam as a heat source is widely used within this manufacturing industry for cooking, baking, frying, as well as for food safety measures that kill microorganisms.

The heating needs of operations carried out in the food and beverage industries typically have low-to-medium temperatures and low flux energy needs, but these energy needs represent a significant portion of the U.S. manufacturing cumulative energy consumed. The energy demands of individual facilities are small compared to the heavy industries, such as petrochemical, steel and cement. However, the number of food and beverage industrial sites far exceeds the number of heavy industry sites, and they are distributed more evenly across the nation.

Electrification opportunities

These heating operations can be optimized for efficiency and converted using electric and hybrid heating (e.g., microwave and other radio frequency technologies, such as induction) as the source of energy. Electric and hybrid process heating can considerably decrease processing times, improve nutrient retention and reduce overall production (and food) costs.

Electric heating

Faster processing times.

Nutrient retention

Improve food quality.

Cost reduction

Lower production costs.

EPIXC’s strategic approach

The goal of EPIXC is to develop electric heating operations and drying technologies for various food processing applications. Processing parameters will be optimized to make the process more economical and minimize nutritional degradation to processed food products. Pilot-scale prototype processing systems will be developed in collaboration with industry partners who are world leaders in manufacturing industrial heating and drying systems.

Through existing and emerging advanced electrified and hybrid process heating technologies, EPIXC is well positioned to advance the competitiveness of U.S. food and beverage production, reduce manufacturing costs, improve product quality, enable broader heat process technology choices, and provide transparent, impartial systems-level analysis to inform technology readiness and adoption decisions.

EPIXC works with established food and beverage manufacturers as well as electrification and hybrid technology developers to drive energy efficiency and other benefits.

Join our mission

If you are interested in joining our mission, become a member today!